Maintenance, Repair, and Operations (MRO) describes the operations and activities related to the upkeep of a plant or facility. This includes physically maintaining the structure or building, the systems operating within the facility, and the equipment used for production. Examples of MRO items are gloves, safety equipment, computers, industrial equipment, consumables, and plant upkeep supplies.

The right MRO solution plays a key factor in supply chain efficiency. Failure to keep up with routine maintenance, repair, and overhauling of systems can halt the manufacturing process and negatively affect the bottom line. Those industries that maintain their maintenance, repair, and operations inventory and optimize their supply chains can more efficiently and economically supply products to customers.

Infrastructure Repair and Maintenance

Infrastructure repair and maintenance include any activities related to the upkeep, cleanliness, and appearance of the grounds of physical structure. Repairing the roof, doors, windows, and loading dock bays, maintaining HVAC systems and lighting systems, waste removal, pest control, and custodial services all fall under this area of MRO.

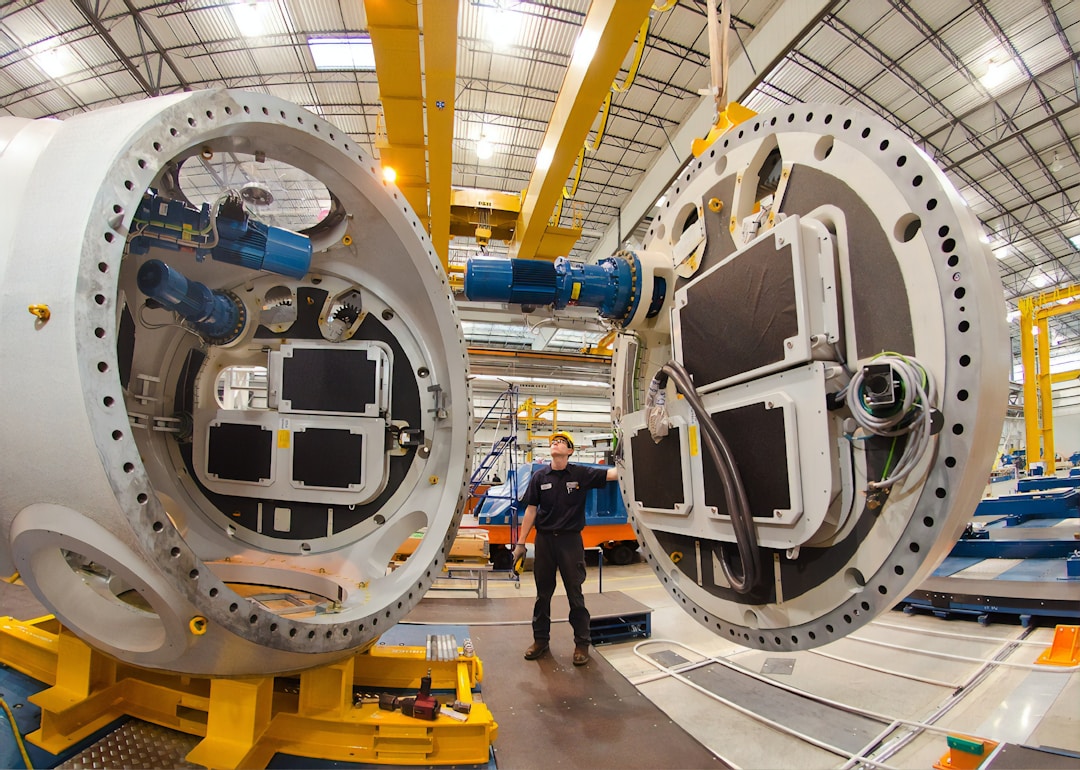

Production Equipment Repair and Maintenance

The maintenance and repair of production equipment focus on achieving the optimal functioning of the vital machinery and systems needed to produce a business's products and services. It helps avoid the costly disruption of unscheduled downtime that could lead to significant revenue loss. The manufacturing sector uses different types of mechanical, electromechanical, or electrical or electronic machinery, each of which has unique maintenance and repair needs.

Material Handling Equipment Maintenance

Material handling equipment is essential for transporting raw material and components to production lines, as well as transporting final products to warehouses or loading docks. This type of equipment includes a range of systems and machinery, both permanent and moveable. Things like forklifts, conveyor systems, bulk containers, jacks, and robotics are all material handling equipment that is essential to the manufacturing process.

Not all MRO suppliers USA and vendors are created equal. Procure Analytics is an industry leader offering the best MRO analytics that will help reduce operating costs. Their team works to optimize your MRO spend and provide you with the data resources needed to succeed. The analytics process uses insights from supplier data to discover all areas of cost savings. PA's technologists lead change management, the adoption of new technology and methods, and increase compliance for industries of all sizes.

Tooling and Consumables

Tooling and consumables are the smaller tools and materials used during the production process. They are used or consumed during production but aren't a part of the finished product. These items include powered and manual hand tools, cutting bits, clamps and joining tools, adhesives and abrasives, personal protection equipment, and janitorial supplies.

The technological advances brought on by the fourth industrial revolution and the impact of automation on routine tasks have led to greater efficiency in human labor. As the current industrial revolution has evolved over the last decade, the adoption of new technology has caused MRO suppliers and vendors to get innovative.

Technological advancements have optimized business operations across industries by allowing human workers to program machines and devices to automate routine tasks. There is concern that automation and the use of artificial intelligence and machine learning will cause human labor to become obsolete. Days 3 offers some useful advice on how laborers can thrive in the era of automation.

The future of work will depend on how adaptable you are to change in the workplace and industry. Consider finding a new job or better job in an emerging field that relates to the new technology and automation tools in use. The best way to prevent job loss in the near future is to learn new skills that will make you invaluable. Technological change and increased automation will encourage occupations to evolve and create new opportunities for the labor market.

Ensuring your supply chain is inventoried with essential MRO items prevents disruptions in the manufacturing process that can lead to revenue loss, limited product availability, and customer dissatisfaction.